Rope Opening Machine for knitting fabric

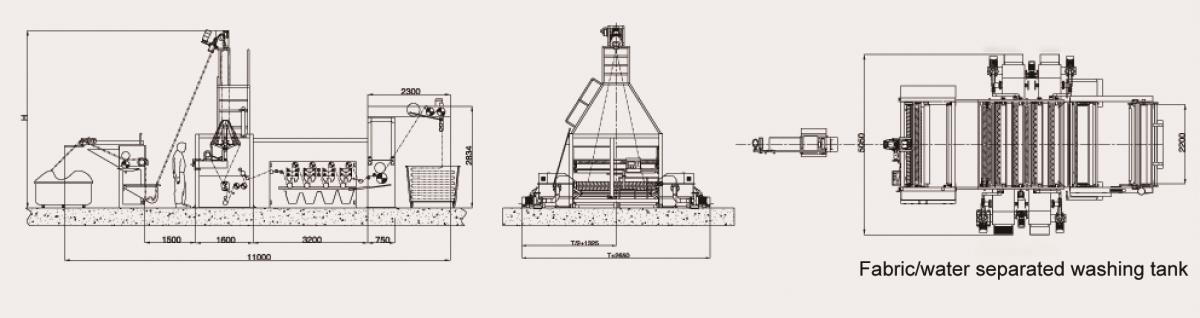

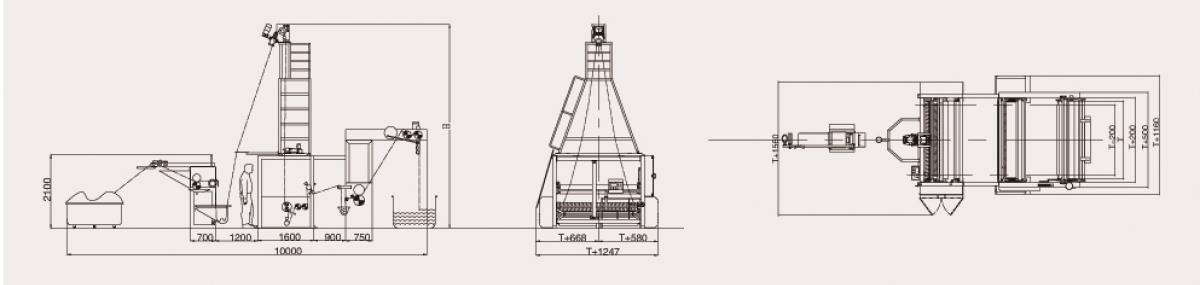

SC-E2 Rope opening slitting washing squeezing line (with fabric/water separated tank)

The cleaned fabric is always separated from the liquid surface of the water tank to prevent secondary pollution. The number of filters in each group of water tanks increases step by step. The cleaner the water is, the better the cleaning effect of the fabric will be. Finally, the desired wool washing purpose will be achieved.

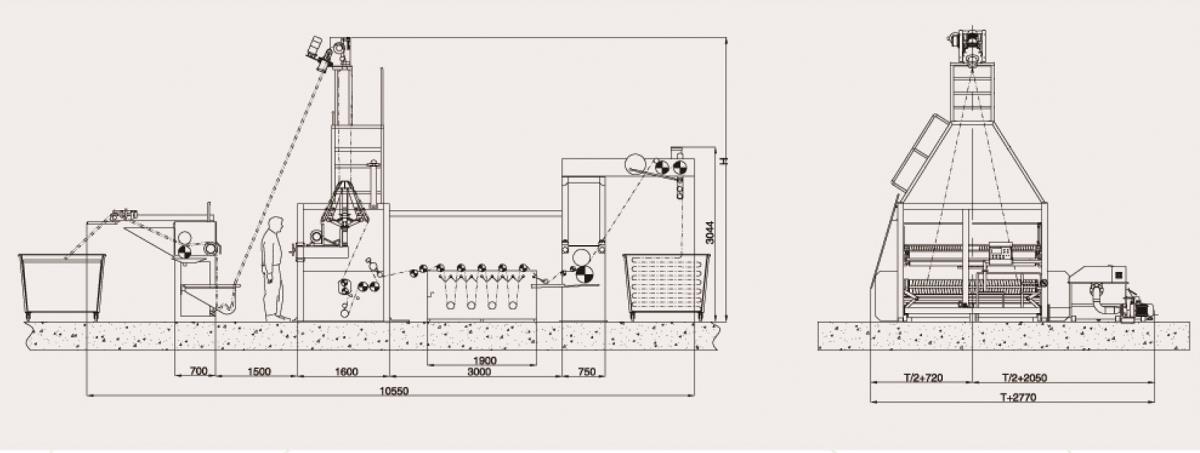

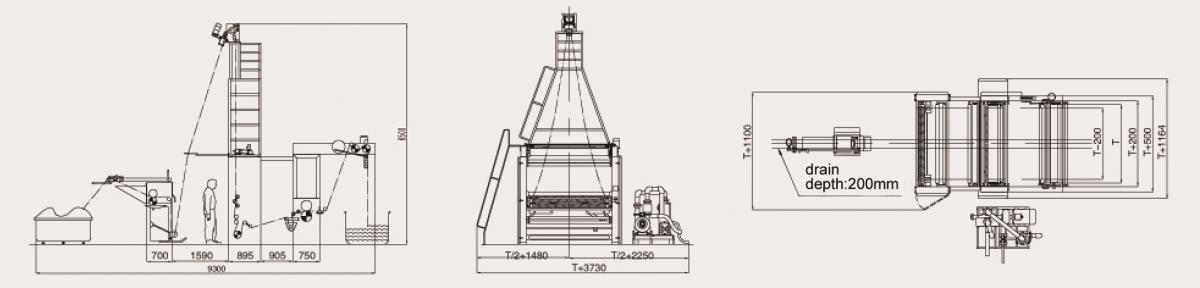

SC-E3 Rope opening slitting washing squeezing line (with high efficient washing tank)

The fabric can be washed adequatedly by spraying when it go into and out of the water surface and repeated four times. At the same time, the water in the washing tank is filtered and used as spray water again, so that it can be recycled to save water.

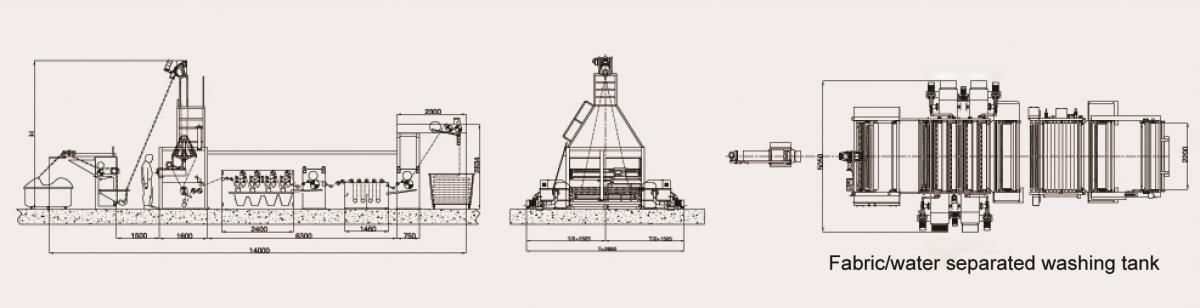

SC-E4 Rope opening slitting washing softening with double squeezing line (double tank)

Advantage: the filter superiority mainly manifests for water conservation, erosion of high efficiency, good effect of removing wool from fabric.

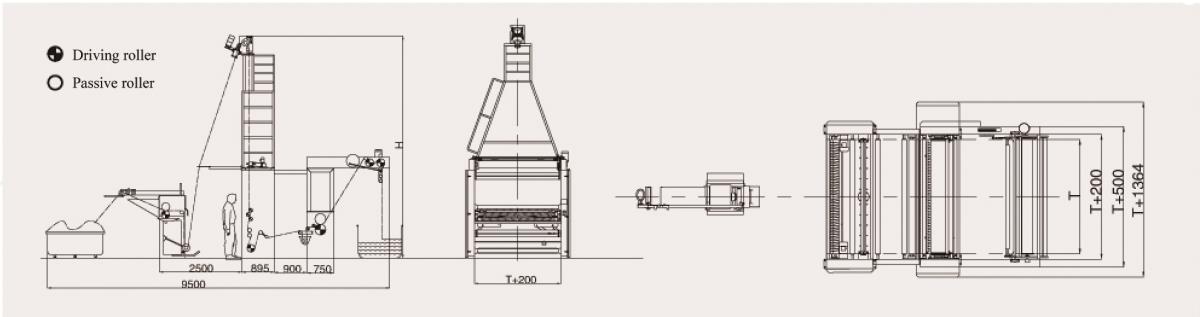

ope Opening Machine for woven fabric

SC-C Rope opening squeezing line

The economic rope opening machine equipped with squeezer, which is suitable for the finishing process of woven and knitting fabrics after dyeing out of cylinder.

SC-C1 Rope opening squeezing line with new host

The conventional rope opening machine equipped with squeezer, which is suitable for the finishing process of woven and knitting fabrics after dyeing out of cylinder.

SC-D Rope opening squeezing and sucting line

A vacuum suction system is added to reduce the moisture content of the fabric, so as to improve the drying speed of the follow-up machine.

Technical Support:YOUWEI Team